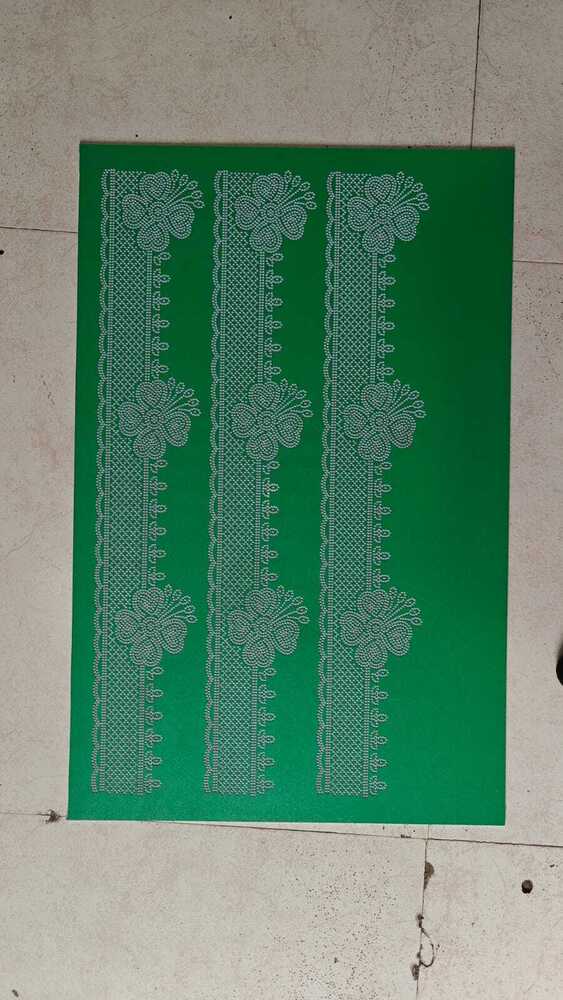

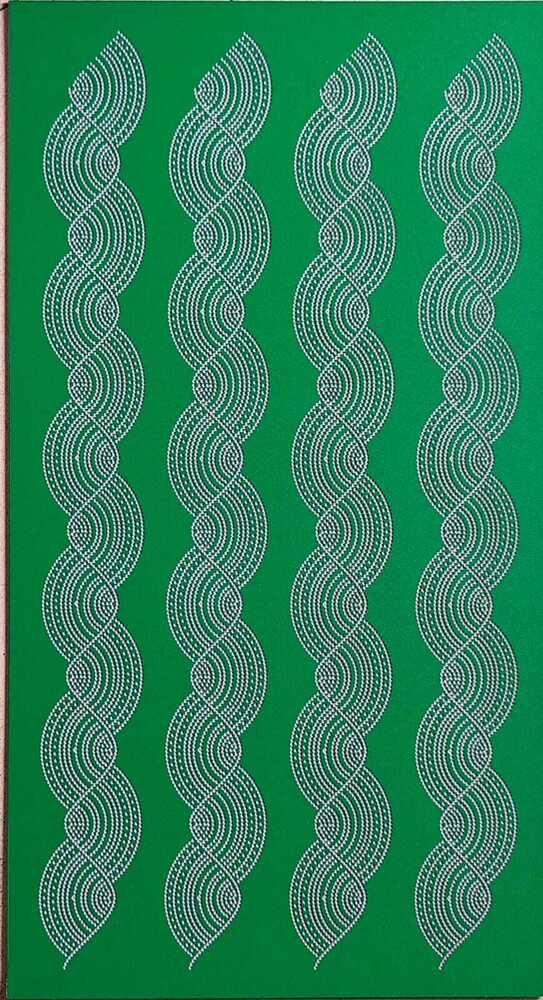

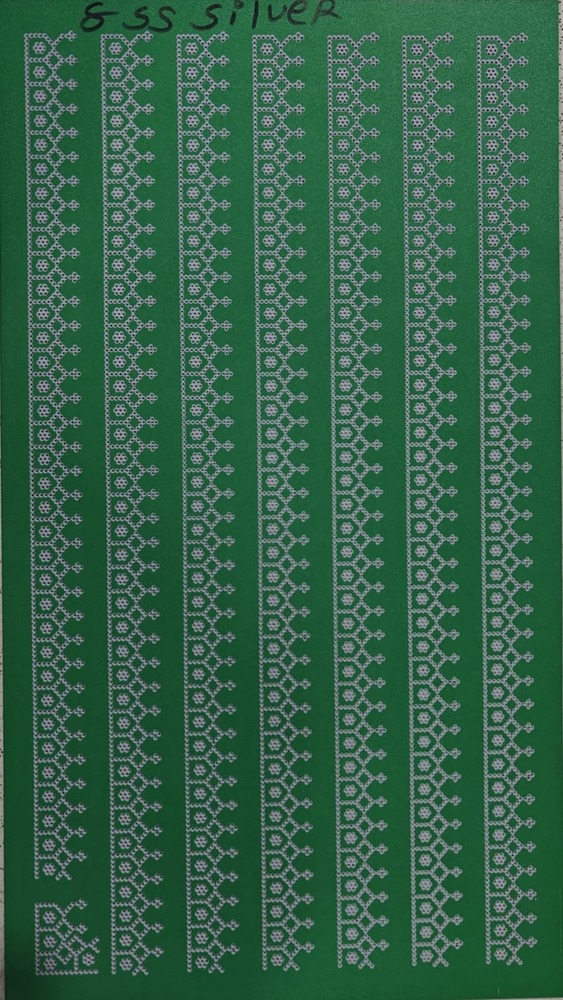

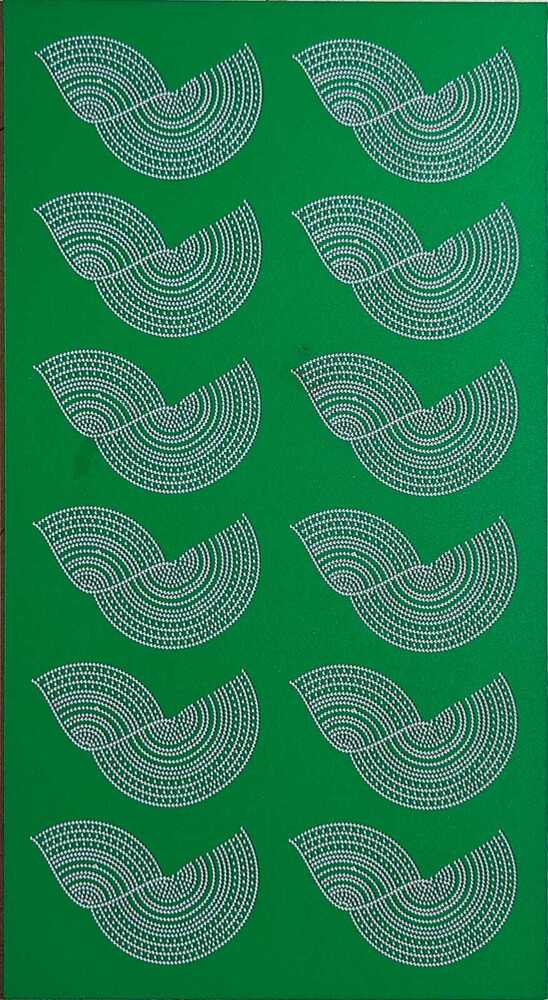

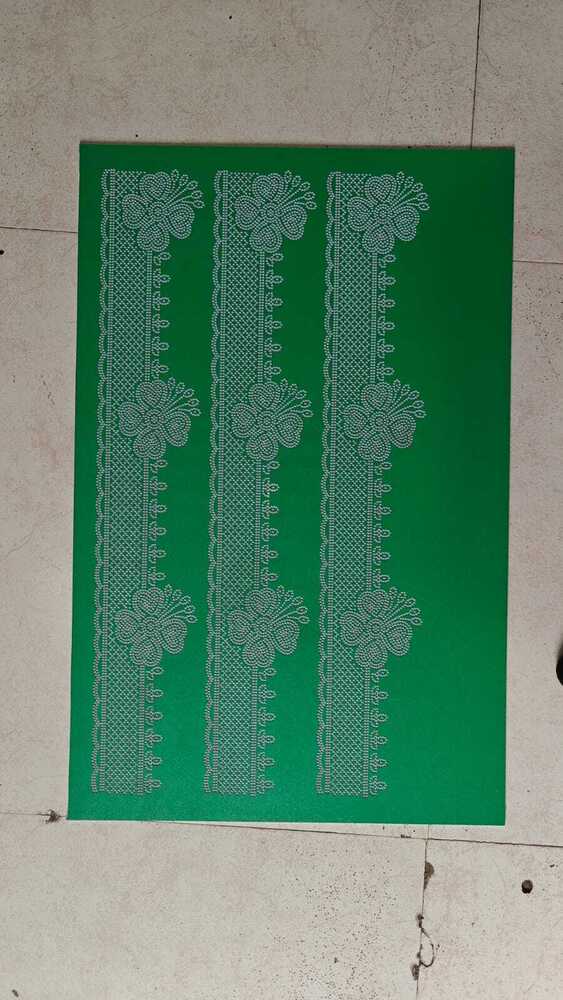

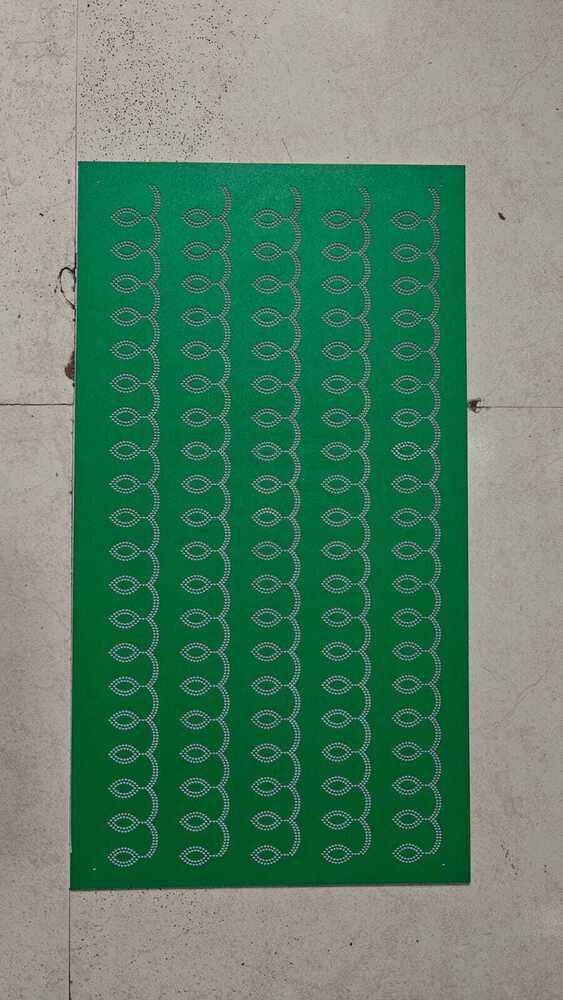

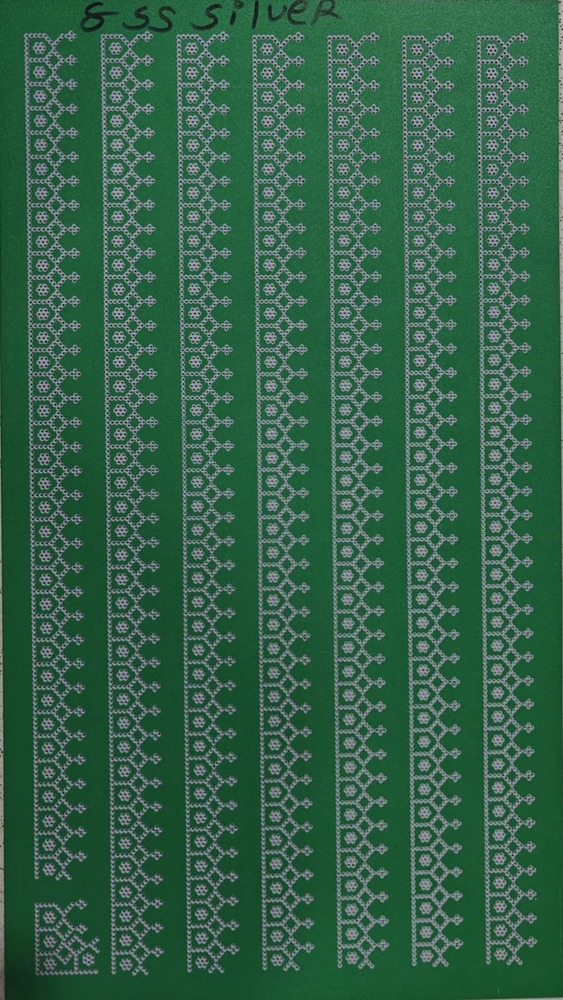

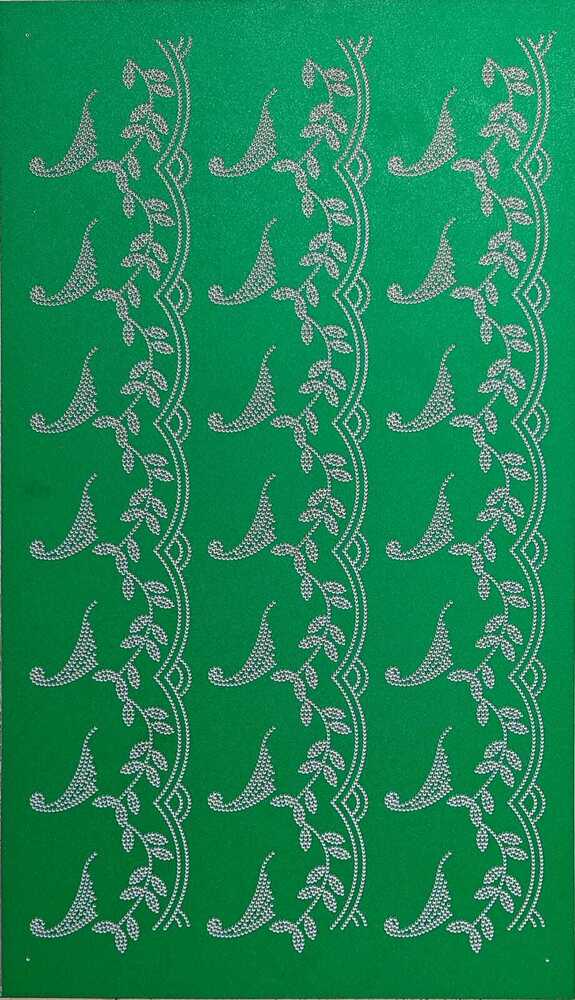

Hot Fix Dye Cutting Designer Sheet

Hot Fix Dye Cutting Designer Sheet Specification

- Drive Motor

- Stepper drive

- Product Type

- Hot Fix Dye Cutting Designer Sheet

- General Use

- Heat transfer, garment decoration, craft design

- Material

- Designer hot fix sheet (PET base)

- Type

- Designer Sheet Cutting Machine

- Capacity

- Suitable for bulk production

- Weight (kg)

- Approx. 35 Kg

- Computerized

- Yes

- Automatic

- Yes

- Cutting Speed

- Up to 800 mm/s

- Cutting Thickness

- 0.2 mm - 1 mm

- Cutting Function

- Hot Fix Dye Cutting with customized design capability

- Cooling System

- Air Cooling

- Drive Type

- Stepper Motor

- Voltage

- 220 V AC, 50 Hz

- Dimension (L*W*H)

- 650 mm x 800 mm x 400 mm

- Feature

- Precise cutting, easy to operate, fast processing speed

- Color

- Golden (custom colors available)

- Motor

- High precision stepper motor

- Mechanical Precision

- 0.05 mm

- Software Detail

- Compatible with standard hot fix software

- Cutting Method

- Die cutting / binary vector cutting

- Control System

- Integrated digital microcontroller

- Cutting Area

- 500 mm x 700 mm

- Cutting Material

- Hot fix transfer films, PET sheets, designer sheets

- Included Accessories

- Blade set, power cable, instruction manual

- Noise Level

- <60 dB

- Minimum Order Quantity

- 1 Unit

- Installation Type

- Desktop / Tabletop

- Operation Mode

- Manual and Automatic

- Safety Protection

- Overheat and overload protection features

- Power Consumption

- 120 W

- Working Environment

- 5°C - 40°C, humidity <85%

Hot Fix Dye Cutting Designer Sheet Trade Information

- Minimum Order Quantity

- 1 Inch

- Supply Ability

- 80 Inches Per Day

- Delivery Time

- 1 Days

- Packaging Details

- As per your requirements

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- It is used to fill the rain stone sheet.*Crafting and Scrapbooking* : Used to cut out shapes and designs from paper, fabric, or other materials.*Packaging* : For creating specific shapes or designs in packaging materials.*Textile Industry* : Used to cut fabric into specific patterns for clothing or accessories.*Labeling* : To cut labels in various shapes for products.

About Hot Fix Dye Cutting Designer Sheet

It is used to fill the rain stone sheet.*Crafting and Scrapbooking* : Used to cut out shapes and designs from paper, fabric, or other materials.*Packaging* : For creating specific shapes or designs in packaging materials.*Textile Industry* : Used to cut fabric into specific patterns for clothing or accessories.*Labeling* : To cut labels in various shapes for products.Efficient and Versatile Cutting Performance

This advanced hot fix dye cutting machine accommodates a variety of materials such as PET sheets, transfer films, and designer sheets, supporting an extensive range of applications. Its bulk production capability, combined with high mechanical precision and a sizeable cutting area, ensures both small-scale custom projects and large production runs are handled with ease.

User-Friendly Operation and Safety

With both manual and automatic operation modes, the machine is accessible to beginners and professionals alike. The inclusion of an integrated digital microcontroller and intuitive hot fix software compatibility streamlines the cutting process, while overheat and overload protection features, along with quiet operation, enhance workplace safety and comfort.

FAQ's of Hot Fix Dye Cutting Designer Sheet:

Q: How do I install and set up the Hot Fix Dye Cutting Designer Sheet machine?

A: Place the machine on a stable desktop or tabletop surface in an environment between 5C and 40C with humidity less than 85%. Connect the power cable to a 220 V AC, 50 Hz outlet, and follow the instructions in the manual to install the included blade set. The machine comes ready for use; simply connect to your computer if you wish to use compatible hot fix software.Q: What materials can this machine cut, and what is the maximum cutting thickness?

A: The machine is designed for designer hot fix sheets and PET-based materials, including hot fix transfer films. It can efficiently cut materials ranging from 0.2 mm up to 1 mm in thickness, making it suitable for most garment and craft design applications.Q: When should I use manual versus automatic operation mode?

A: Manual mode is ideal for precise, small-batch or detailed cuts where direct control is required, while automatic mode is best suited for larger or repeat production runs for efficiency and consistency. Both modes ensure easy operation and accurate cutting based on your specific project needs.Q: Where can I use this machine, and what are the basic space and environment requirements?

A: This machine is designed for indoor use on a standard table or desk. Ensure the room temperature remains between 5C and 40C, with relative humidity below 85%. The compact footprint (650 mm x 800 mm x 400 mm) makes it suitable for studios, workshops, or small production units.Q: What is the process for creating custom hot fix designs with this machine?

A: Design your pattern using compatible hot fix software, then transfer the file to the machine. Load your chosen material, set the desired operation mode, and start the cutting process. The stepper motor and digital microcontroller ensure your design is rendered with mechanical precision.Q: How does the machine ensure user safety and prolong equipment life?

A: The device incorporates overheat and overload protection features, preventing potential hazards and extending operational lifespan. Air cooling maintains optimal operating temperatures, and the machine operates at a noise level below 60 dB for a comfortable workspace.Q: What are the key benefits of using the Hot Fix Dye Cutting Designer Sheet machine for garment decoration or crafts?

A: It offers precise and rapid cutting, is easy to operate, and supports high-volume production with minimal noise. Customizable color options and integration with hot fix software enhance product flexibility, while overheat and overload protection ensure safe, reliable performance.

Price 1200.00 INR/ Inch

- Minimum Order Quantity

- 1 Inch

- Supply Ability

- 80 Inches Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jarkhan Die Cutting Category

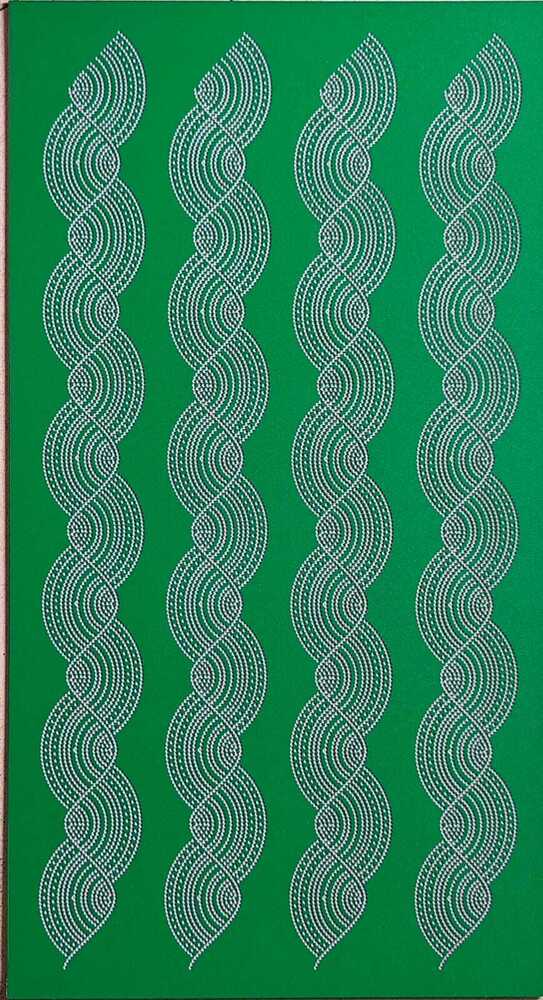

Jarkan Die Cutting Designer Sheet

Minimum Order Quantity : 1 Inch

Computerized : Yes

Automatic : Other, Semiautomatic operation

Control System : Digital programmable control

Color : Other, Multicolor, patterned

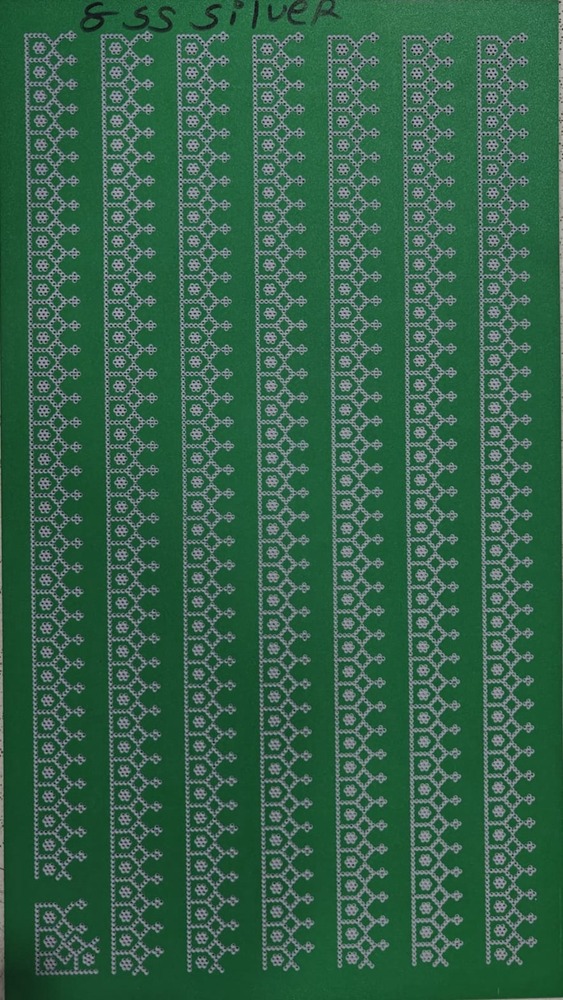

Border Design Jarkan Die cutting sheet

Minimum Order Quantity : 1 Inch

Computerized : No

Automatic : No

Control System : Manual

Color : Other, Silver metallic finish

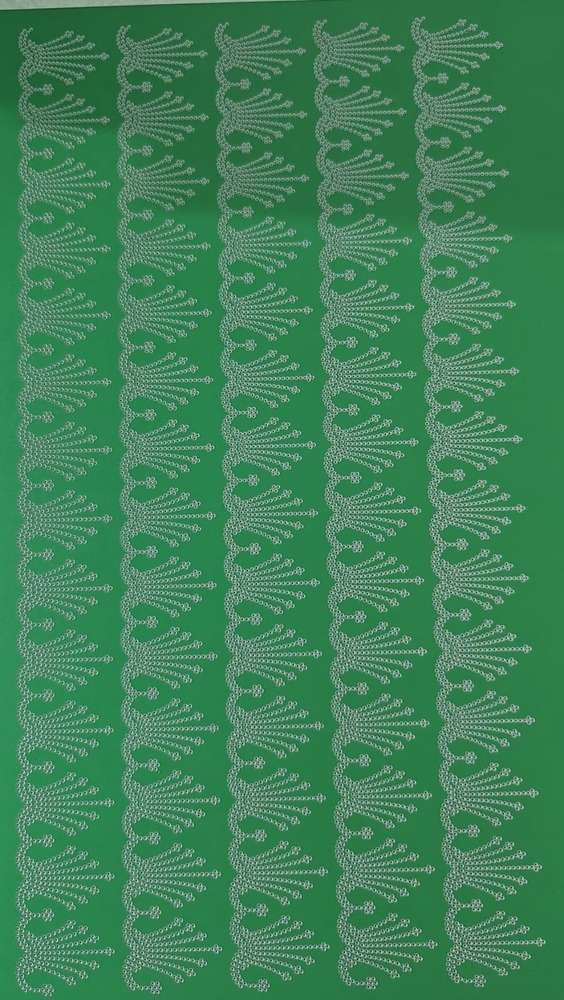

Hot Fix Dye cutting sheet

Price 1200.00 INR / Inch

Minimum Order Quantity : 500 Inches

Computerized : Yes

Automatic : Yes

Control System : Manual

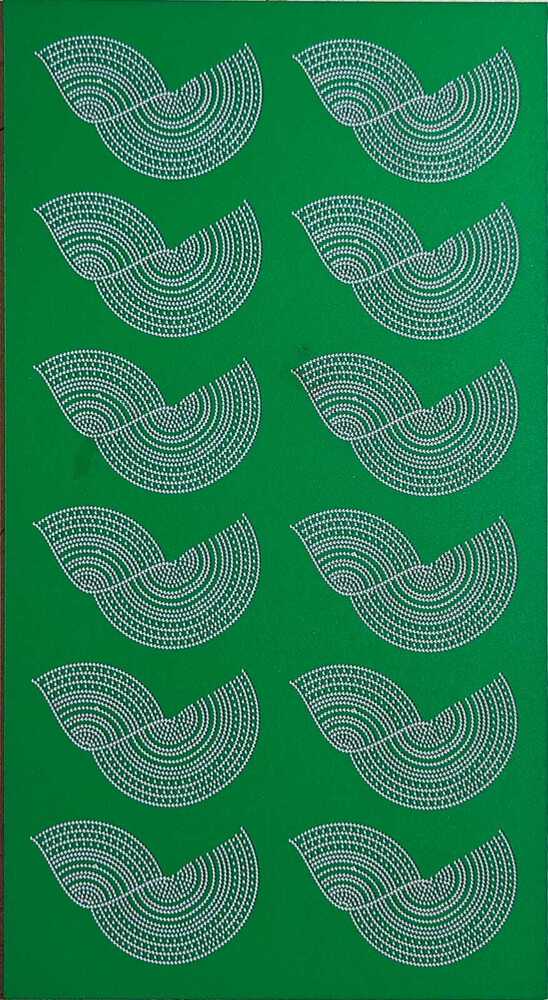

Jarkan Designer dye cutting

Price 1100 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : No

Control System : Manual

Color : Green

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese